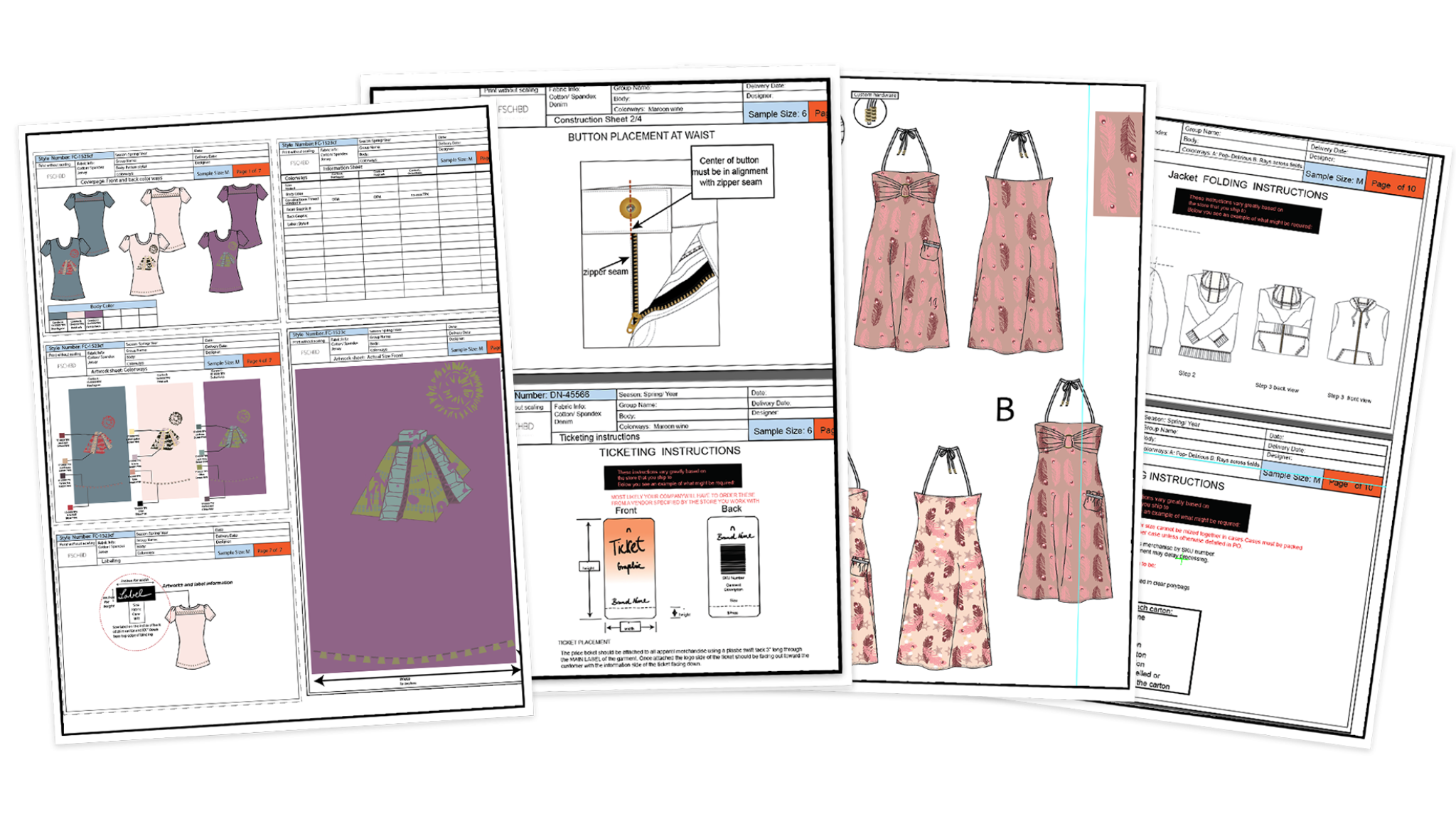

Tech pack template bridge the gap between fashion designers and manufacturers. They serve as the universal language of garment production.

While no standard format exists, these detailed documents contain all the significant specifications needed to transform designs into finished products.

A complete tech pack template makes the design process smoother and helps manufacturers deliver accurate results. The three-page template we use covers detailed measurements, material specifications, woven labels, and hang tags.

Technical packs also include vital elements like style overviews, product sketches, and label details that manufacturers need to replicate your designs perfectly.

This piece will show you how to create professional tech pack templates that work well with manufacturers.

You’ll learn about everything from digital tools to quality control measures. The goal is to help you build complete and practical tech packs that deliver results.

Essential Components

A well-laid-out tech pack template works as a detailed blueprint that guides manufacturers through production with specific components.

The Bill of Materials (BOM) is the foundation that lists every component needed to create a garment. It has fabrics, trims, thread, closures, labels, and packaging materials.

The BOM helps determine accurate costing and pricing while maintaining quality consistency across production batches.

Technical design sketches are a vital element that showcase both front and back views of the garment in black and white format.

These sketches feature precise callouts with construction specifications, stitching techniques, and material placement details.

The measurement specification sheet expands on measurements for different components and defines allowable tolerances to maintain consistency during mass production.

Construction details communicate assembly instructions effectively. This section specifies seam types, stitch density, and assembly techniques for each garment component.

Designers often add zoomed bubbles to highlight specific features that help manufacturers understand exact requirements for tiny components.

The graded specification sheet, known as the spec sheet, maintains proper sizing in garment variations. This document has Points of Measurement (POM) guides that line up manufacturers with specific measurement requirements.

Quality control and testing details must appear early in the tech pack so factories can incorporate these specifications into unit costs.

Packing and labeling instructions complete the vital components with requirements for labels, packaging materials, and specific polybag types. These specifications help manufacturers provide accurate unit costs early in development.

The tech pack has a section to track revisions and changes that helps designers maintain a clear history of modifications throughout the development cycle.

Digital Tools for Tech Pack Creation

Digital tools have made creating detailed tech packs easier by giving designers quick ways to document and share product specifications.

Adobe Illustrator is the go-to tool to create technical sketches, especially with design packs that focus on visual elements. These sketches blend naturally into spreadsheet-based templates for complete documentation.

Microsoft Excel and Google Sheets are resilient platforms that handle technical specifications well. These spreadsheet tools are great at managing numerical data and work best with graded specs and measurement calculations.

Designers typically combine Adobe Illustrator’s visual features with spreadsheet capabilities to build complete tech packs. The spreadsheet templates include built-in formulas that eliminate mathematical errors.

Cloud-based collaboration platforms have revolutionized tech pack development. These specialized tools help teams communicate with manufacturers through up-to-the-minute updates.

Many platforms now include features like automated grading, version control, and centralized asset management. Designers can track changes through automated logs that record user updates and timestamps.

Digital tech pack software brings new features that make the production process smoother. To name just one example, some platforms connect directly with 3D design software, which helps manufacturers visualize designs better.

Of course, these tools help create detailed care instructions in multiple languages, among other complete bills of materials.

Different digital tools working together create distinct advantages. Spreadsheets link cells to keep data consistent, so you only need to input information once.

Adobe Illustrator remains essential to create vector graphics and technical sketches with precise callouts. Most designers keep their main template in either spreadsheets or Illustrator and copy finished elements between platforms as needed.

Quality Control in Tech Pack Development

Quality control is central to successful tech pack implementation. It makes sure garments meet specific standards during production.

Quality Assurance (QA) builds quality into each manufacturing step, while Quality Control (QC) checks the final product’s quality.

The first step in quality measures starts with setting exact tolerance levels in measurement specifications. These tolerances show acceptable variations, which usually range from 1/4 inch to 1/2 inch for main dimensions.

A chest measurement of 40 inches means anything between 39.5 and 40.5 inches works well under standard tolerance rules.

The Fit Sheet helps document measurements of physical samples. Designers can add custom columns for actual measurements to calculate if samples match the given tolerances.

Quality control goes beyond just measurements and includes several testing methods:

- Physical Testing: Checks durability, strength, and flexibility

- Chemical Testing: Looks for harmful substances

- Wash and Wear Testing: Tests product lifecycle

Random inline inspections check stitching quality, seam strength, and pattern arrangement during production.

After production, inspectors use the AQL (Acceptable Quality Limit) table to set inspection sample sizes and allowed defects. Fashion industry’s standard AQL levels range from 1.0 to 4.0, where lower numbers mean stricter quality standards.

Teams sort defects into three groups based on how serious they are:

- Critical damages: Products that can’t be sold

- Major damages: Big issues affecting looks but still sellable

- Minor damages: Small defects that teams can fix

Tech packs work as reference guides through these quality control stages.

They keep detailed records of stitching mistakes and wrong specifications to stop errors from happening again. Strict QC standards reduce problems and delays. They streamline processes and build brand reliability.