Let’s face it – the ocean holds incredible potential, but getting to those resources isn’t exactly a walk in the park. Picture this: valuable minerals, energy sources, and scientific discoveries sitting thousands of feet below sea level. The catch? They’re locked away under crushing pressure and extreme conditions that would destroy standard equipment in minutes. That’s where deep offshore technology comes in, designed to withstand these harsh environments and unlock the ocean’s hidden treasures.

Here’s the reality check: While oceans cover 70% of Earth’s surface, we’ve barely scratched the surface of what lies beneath. Working at depths between 1,000 to 5,000 feet isn’t just challenging – it’s pushing the boundaries of what engineering can achieve. Think intense pressure that could crush a car like a soda can, unpredictable weather that can change in minutes, and delicate ecosystems that need protecting.

But here’s the good news: Deep offshore technology is changing the game. We’re not just talking about basic underwater equipment. Modern solutions like autonomous underwater vehicles, smart monitoring systems, and advanced subsea production setups are making the impossible possible. These aren’t just fancy toys – they’re robust, reliable tools designed specifically for the harsh realities of deepwater operations.

Why does this matter? Because these technological breakthroughs aren’t just about accessing resources – they’re about doing it right. We’ll explore how these innovations handle the technical challenges while keeping environmental protection and economic viability in focus. From pressure management to ecosystem preservation, you’ll see exactly how modern engineering tackles the ocean’s toughest challenges.

So grab your virtual diving gear – we’re about to explore how cutting-edge technology is unlocking the secrets of the deep, one innovation at a time.

Deep Offshore Technology: Critical Challenges in Deep Sea Engineering

The hard truth? Working in the deep sea isn’t just challenging – it’s like trying to build a house in space. At depths of 36,000 feet, we’re dealing with pressure that hits eight tons per square inch – that’s 1,000 times what we experience at sea level. You thought your pressure cooker was intense? Think again.

Extreme Pressure and Temperature Management

Let’s talk about what we’re really up against here. Picture being at the average ocean floor depth of 3,800 meters. The pressure? A whopping 380 times greater than what we feel up here. Here’s where smart engineering comes in: We use spherical or cylindrical pressure housings because they spread out all that crushing force evenly across their surface. It’s not just about being strong – it’s about being smart with design.

Subsea Equipment Reliability Issues

Want to know what keeps engineers up at night? It’s not just the extreme pressure – it’s everything else that can go wrong down there. Subsea control systems face a constant battle against falling objects, fishing nets, and environmental factors that could trigger critical failures. The most vulnerable parts? Our reliability tests show it’s the subsea distribution modules, fiber optic components, and those crucial temperature-pressure sensors.

Environmental Impact Concerns

Here’s where things get really tricky. Mining activities can cause significant disruption to marine ecosystems. We’re not just talking about a little disturbance – we’re facing some serious environmental challenges:

- Equipment deployment stirring up the seabed

- Sediment plumes that could suffocate marine life

- Risk of releasing trapped carbon dioxide from the seabed

The reality check? We can’t just focus on getting the job done – we need to protect what’s down there too. That’s why we’re seeing more advanced monitoring systems and strict protocols being put in place. It’s about finding that sweet spot between getting results and being responsible stewards of our oceans.

Advanced Deep Offshore Technology Solutions

Ready to see what’s changing the game in deep sea tech? The latest innovations aren’t just improvements – they’re completely reshaping how we work underwater.

AI-Powered Monitoring Systems

Remember when monitoring subsea assets meant hoping for the best? Not anymore. Advanced Ocean Systems has cracked the code with AI-driven monitoring that works alongside smart robotics for defense and offshore energy. These aren’t your average monitoring systems – they’re tough enough to handle depths of 3,000 meters while keeping a constant eye on subsea assets.

Here’s something cool: The ExtremeEdge OLM system uses edge AI so cleverly that it can run for over ten years on its own, thanks to smart battery management. Think about that – a decade of autonomous operation in one of Earth’s harshest environments.

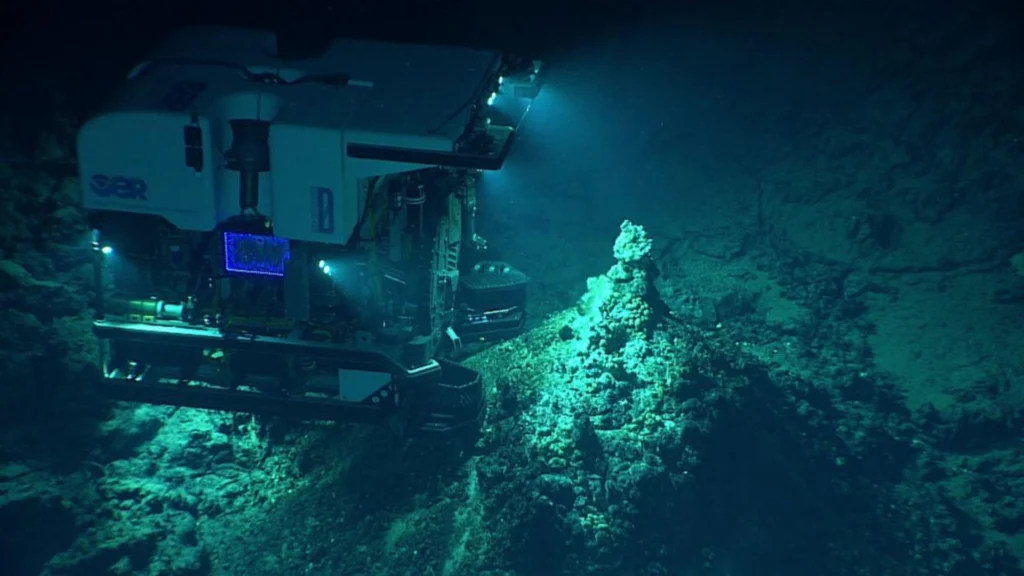

Deep Offshore Technology: Autonomous Underwater Vehicle Innovations

Want to know what’s really exciting? AUVs are changing everything about deep sea exploration. These smart robots tackle pre-planned missions without anyone holding their hand. Take the LRAUV (Long-Range Autonomous Underwater Vehicle) – it’s like the Tesla of underwater exploration:

- Cruises beyond 1,000 kilometers in ultra-low power mode

- Dives down to 1,500 meters without breaking a sweat

- Packs advanced gear for everything from microbial sampling to detailed seabed mapping

Smart Sensor Networks for Real-time Data

You know how your smart home devices talk to each other? Well, the Subsea Internet of Things (SIoT) does the same thing – but under extreme pressure. These networks use wireless sensors to deliver real-time operational insights. And check this out: Subsea Data Systems’ SMART Cable systems come with sensor-packed repeaters that track seismic activity, pressure, and temperature non-stop.

The results? These tech combinations are doing things we only dreamed of before. AI-powered bots now carefully collect resources while protecting fragile ecosystems. Plus, these smart machines plan and adjust their missions on the fly, making decisions based on real-world conditions. It’s not just about working better – it’s about working smarter in one of Earth’s last frontiers.

Engineering Deep Offshore Technology Infrastructure

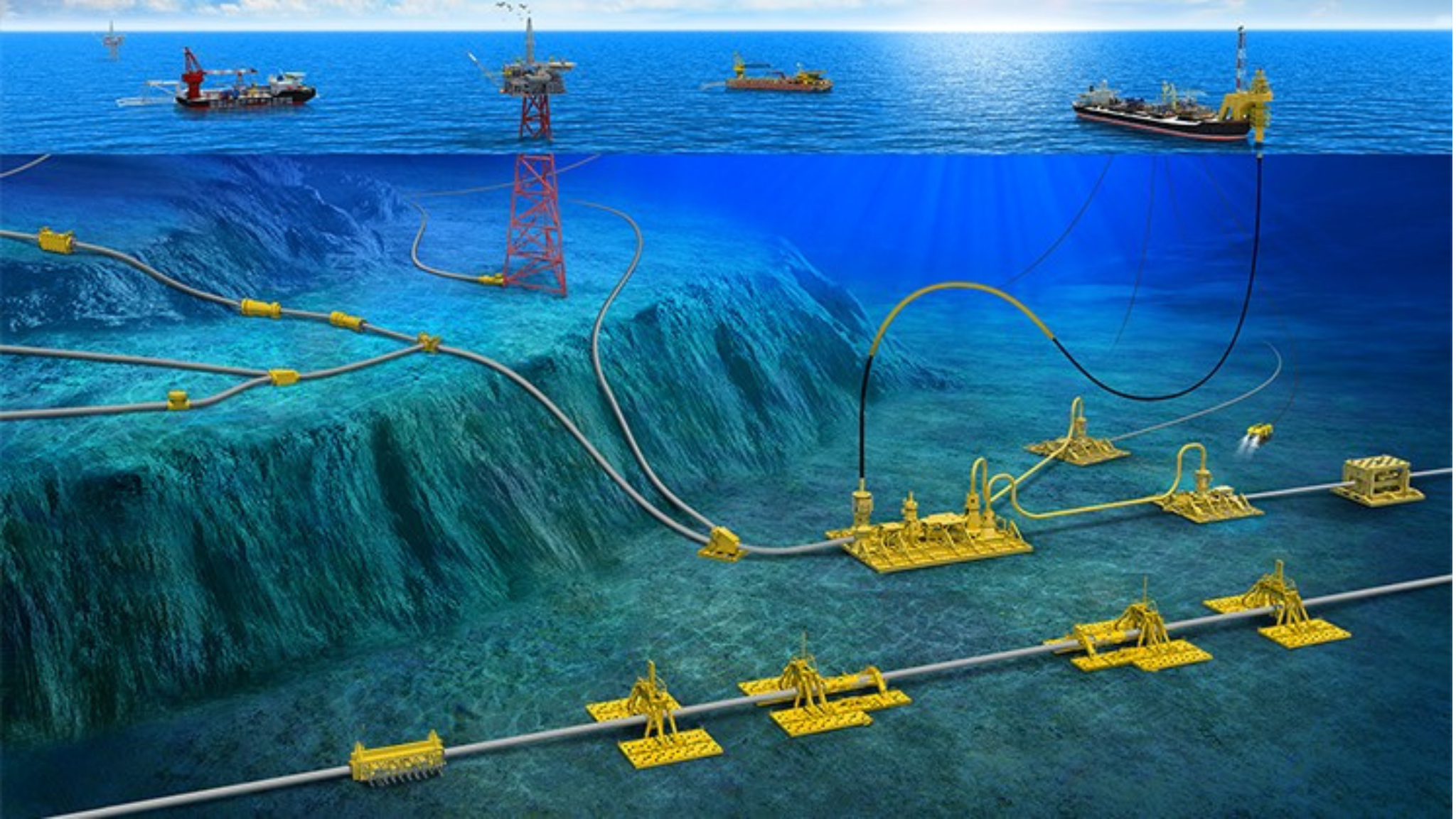

The backbone of modern offshore operations? It’s the subsea production systems that make energy extraction possible at depths we once thought impossible. These aren’t static setups – they’re smart systems that adapt to changing basin conditions, no matter what phase of development you’re in.

Next-generation Subsea Production Systems

Modern subsea systems are changing the game with standardized, plug-and-play designs across all components. Think of it like building blocks – each piece needs to work perfectly with the others:

- Subsea trees keeping operations safe

- Smart manifolds handling testing and sampling

- Wellheads that laugh in the face of pressure

- Control systems running the show remotely

- Power umbilicals feeding the processing systems

- Flowline connections tough enough for anything

Innovative Pipeline Design and Installation

Pipeline installation has come a long way. S-lay technology has already put over 20,000 km of subsea pipeline in place worldwide. But here’s where it gets interesting – the J-lay method stepped up the game for deep-water work, handling pipes from 10″ to 50″ across. The clever part? It cuts down pipeline stress by keeping the touchdown point close to the seabed.

Remote Operation Centers

The future of offshore operations is already here. Since 2015, Onshore Remote Operations Centers (OROCs) have popped up in Stavanger, Morgan City, Aberdeen, and Macaé. These aren’t just control rooms – they’re command centers handling everything from day one commissioning to final decommissioning, plus all the inspections and maintenance in between.

The Liberty™ Resident System shows exactly what these centers can do, packing 550 kwh of battery power for remote operations. The best part? It keeps things running without constant vessel support, cutting both costs and carbon footprint.

Economic Impact of Deep Offshore Solutions

Let’s talk money – because deep offshore operations aren’t cheap. Want to know the real numbers? A single collection vehicle will set you back USD 10-20 million. But that’s just the start. Support vessels? They’re in another league entirely, demanding USD 400-600 million. And if you’re thinking about building a processing plant, you’re looking at USD 3-4 billion.

Deep Offshore Technology: Cost-Benefit Analysis of New Technologies

Here’s where things get interesting. The ongoing costs mainly come from keeping equipment running and staying up-to-date with tech. Those fancy advanced material preparation and high-temperature treatment systems? They add another USD 300-500 million to your bill.

But don’t let these numbers scare you. The payoff can be huge. One major operator just reported USD 500 million in value creation during 2023 thanks to AI-driven solutions. That’s not just impressive – it’s game-changing.

Operational Efficiency Improvements

Smart tech investments are paying off big time. Check out these wins:

- Ships sailing themselves – cutting fuel costs and crew needs

- Worldwide support at your fingertips – no travel needed

- Equipment that tells you when it needs attention – maximizing uptime

Investment Returns in Deep Sea Projects

Ready for some real talk about returns? They vary wildly depending on where you’re working and what you’re after. SMS mining and polymetallic nodule extraction are showing some serious promise. The numbers tell an interesting story: potential annual revenues hitting USD 2.3 billion, with operational costs around USD 1.1 billion.

But here’s the catch – market prices are about as stable as a ship in a storm. Take cobalt: even with electric vehicle production shooting up 2,000% between 2016 and 2023, prices actually dropped by 10%. The lesson? You better do your homework before diving into deep offshore ventures.

Conclusion

Let’s be real – what we’re achieving in deep offshore technology is nothing short of amazing. We’re not just reaching depths beyond 3,000 meters – we’re doing it safely and responsibly. Through AI-powered monitoring systems, autonomous underwater vehicles, and smart sensor networks, we’re turning science fiction into reality while protecting our oceans.

Remember those “impossible” challenges we talked about earlier? Here’s what changed the game: Engineering solutions that laugh in the face of pressure 380 times stronger than what we feel up here. Subsea production systems that keep running reliably in conditions that would crush standard equipment. Remote operation centers that run the show from dry land, cutting both costs and environmental impact.

The numbers tell an exciting story. Sure, the initial investment might make your eyes water – we’re talking billions of dollars here. But when you see efficiency improvements through AI and autonomous operations generating $500 million in value (like we saw in 2023), you realize this isn’t just possible – it’s profitable.

Here’s what gets me excited about the future: We’re not just pushing boundaries – we’re doing it right. Advanced monitoring systems keep watch 24/7. Strict protocols ensure we’re not cutting corners. Smart engineering solutions help us extract resources while protecting marine ecosystems. The deep ocean isn’t just our final frontier – it’s our chance to prove we can develop technology that works in harmony with nature.

Want to know the best part? We’re just getting started.